PROPERTIES

- Low cost

- Outstanding thermoforming characteristics for deep drawn forming

- Good machinability

- Easy to assemble with adhesives or solvents

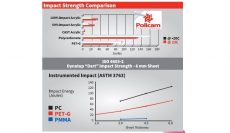

- High impact strength even in low temperatures

- Higher chemical resistance

- Easy to paint or print on

- Available in a wide variety of colors

Save COST, Go HIPS

HIPS (high-impact polystyrene) is the most versatile plastic sheet to guarantee trouble-free processing, giving flexibility of forming, offering enhanced impact resistance as well as enormous cost efficiency.

Ultimate printing solution for digital printing world… Policam HIPS sheets in Matt/Gloss and Matt/Matt options offer high-end printing results and brilliant colors.

It is preferred material for vacuum formers and screen printers who need to turn out high quality work on limited budgets. HIPS finds its way in a wide variety of applications, from bathroom cabinet door lamination to bath tub and shower trays front panels, from point of sale displays to car roof cargo boxes and to furniture parts.

Offered in 48″ X 96″ as well as 50″ X 99″ sizes, starting from 0.020″ up to 0.177″

Unmatched quality

Global Industry Players look for exceptional quality to be a part of their own branding.

World’s leading refrigerator manufacturers confirm our quality. Our top quality HIPS sheets are not only demanded by their plants in Europe but also by the plants overseas.

Işik is not only a sheet producer. Our R&D team working in close cooperation with factories’ production departments, offers the solutions they need. Our extensive material and processing knowledge ensures to meet our customers’ demanding specifications and provide a trouble free run in the assembly lines.

For refrigerator inner liner production, we only use selected ESCR (Environmental Stress Crack Resistance) material, designed specifically for large appliance extrusion/thermoforming applications. This advanced polystyrene resin allows production of thinner refrigerator liners with more homogeneous thickness distribution and improved environmental stress crack resistance compared with conventional high-impact polystyrene (HIPS) resins. In addition, ESCR resins enable significant cost reductions via processing and productivity advantages, and increased rigidity with reduced scrap levels.

IŞIK PLASTİK delivers over 3000 tons of HIPS annually to the world’s leading refrigerator manufacturers.

Just name it

Our product development team is ready to listen your needs and to offer the solutions you need:

- Multilayer production options

- Anti-bacterial surface treatment

- Matt- gloss finishes

- Corona treatment

- UV treatment

- Custom colours

- Desired degree of impact strength

- and many more…

Ultimate printing solution: HIPS

Ultimate printing solution for digital printing world… Policam HIPS sheets in Matt/Gloss and Matt/Matt options offer high-end printing results and brilliant colors.

HIPS (high-impact polystyrene) is the most versatile plastic sheet to guarantee trouble-free processing, giving flexibility of forming, offering enhanced impact resistance as well as enormous cost efficiency.

It is preferred material for vacuum formers and screen printers who need to turn out high quality work on limited budgets. HIPS finds its way in a wide variety of applications, from bathroom cabinet door lamination to bath tub and shower trays front panels, from point of sale displays to car roof cargo boxes and to furniture parts.

Offered in 48″ X 96″ as well as 50″ X 99″ sizes, starting from 0.020″ up to 0.177″

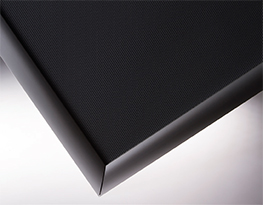

We serve to snap frame market with our specially textured gray polystyrene back panels. They are:

• Easy to machine

• Break resistant

• Easy to clean

• Weather proof

Thickness: 1,0 mm – 1,3 mm

Sizes: Customer specific

Colors: Gray

Refrigerators and freezers have become more complex in their internal design resulting in the need of complex shapes, deep draws and sharp corners. Our high impact polystyrene (HIPS) sheets are manufactured with enhanced ESCR (Environmental Stress Crack Resistance) resins to meet manufacturers demanding needs. With their superior mechanical performance our sheets provide high impact strength, good elongation and heat distortion properties as well as improved chemical resistance, especially against PU foam.

Thickness: 1 mm – 6 mm

Width: Max. 1500 mm

Sizes&Colors: Customer specific

To complete their designs, furniture industry need thermoformable, paintable, impact and chemical resistant and yet economically reasonable materials. High impact polystyrene sheets fill in the gap. Our custom coloured sheets can be ordered cut-to-size to customer specifications.

Thickness: 1 mm – 6 mm

Width: Max. 1500 mm

Sizes&Colors: Customer specific

HIPS is also a popular choice in the sanitary ware industry to make bath panels and basins, where the physical properties and aesthetic qualities of the material are best exhibited.

Their excellent chemical resistance protects them against most detergents.

Thickness: 2 mm – 5 mm

Width: Max. 1500 mm

Sizes&Colors: Customer specific

High impact grades of PS find a wide range of use in automotive industry because of their superior characteristics:

• Roof and ski boxes with high demands in respect of colour fastness

• Heavy goods vehicle parts, such as spoilers, coverings, pick-ups

• Parts of agricultural machines (tractor roofs, motor coverings, mud-guards)

Thickness: 2 mm – 6 mm

Width: Max. 1500 mm

Sizes&Colors:ß Customer specific